For Gas

- 조회수

- 1029

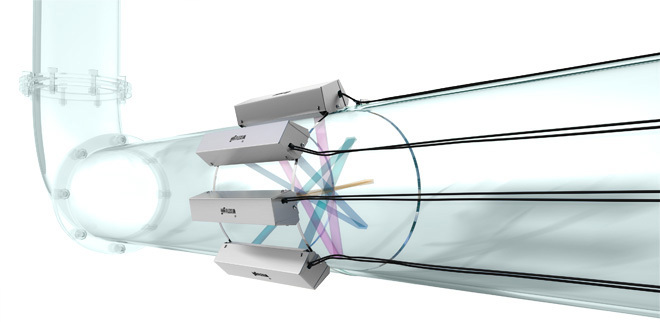

4-Beams for unrivalled Precision, Reliability and Repeatability

The FLUXUS G706 combines highest precision with the advantages of non-invasive ultrasonic gas flow measurement.

With its 4 beams, in reflect mode providing 8 paths through the gaseous medium, the meter averages the result of up to 4 planes. This arrangement averages out cross-flow profile disturbances and achieves the optimum non-invasive compensation. On longer straight runs, the 4-Beam meter achieves outstanding accuracy performance due to the individually averaged path effects and can thus be used for redundancy measurements of custody transfer meters or leak detection.

Temperature compensated transducers, unique digital signal processing with superior noise suppression combined with a highly rugged design care for an unrivalled degree of reliabilialy, durability and accuracy - ensuring perfect operation of the system under the harshest field conditions and makes it even suitable for installations buried in the ground (IP68 rated).

Custody Transfer Accuracy

The G706 is capable of accuracy in the Custody Transfer class. Clamp-on meters installed will contain some uncertainty due to pipe uncertainties and pipe geometry. These can be minimized with careful installation, precise pipe wall measurements and especially based on the effects of the multiple 4-channel measurement of the G706. While installed “out of box” custody transfer accuracy is not possible, in many pipeline services like check-metering, leak detection and others, it can be possible to calibrate the meter in-situ to achieve Custody class accuracy (proven by industry independent Calibration Facilities - test reports are available upon request).

Advantages

Easy installation without process outages

When creating a new flow measurement point, a significant part of the costs are incurred by the installation work (line shut-down, pipe cutting, pipe flushing, etc.). These costs are significantly reduced using the F706 clamp-on technology that requires zero impact on pipe integrity while commissioning.

• Highly Economical: No heavy equipment necessary for installation, thus being the ideal solution for remote locations, or poorly accessible areas.

• 100% plant availability: The non-invasive measurement technology does not require any process shut-downs - neither for installation nor for any potential maintenance efforts

• Extremely low maintenance – virtually zero maintenance due to use of solid couplant pads instead of high maintenance gels

• Safety: The F706 clamp-on meter does not add any leakage risk. It also does not require any flanges or gaskest

Laboratory Accuracy under Field Conditions

High accuracy and proven laboratory performance under reference conditions is one task. Accuracy under field conditions is quite another thing:

• FLEXIM‘s transducers automatically compensate for ambient temperature changes – according to ANSI/ASME MFC-5.1-2011. This ensures no false measurement readings during temperature swings (day / night)

• FLEXIM‘s transducers are carefully paired according to their individual properties. This process lays the foundation for superior accuracies over a wide temperature and application range. It also ensures a negligible zero offset and facilitates the measurement of very low flow rates. There is no need for zeroing, or programmed “automatic zero” workarounds.

• FLEXIM‘s transducers are all individually factory calibrated, with storage of the calibration data on a “Sensprom”chip. The calibrated transmitter automatically reads the individual calibration data, avoiding potential errors and making transducer exchanges easy.

For FLEXIM, accuracy is a topic we take seriously. FLEXIM‘s specified installed-accuracy claims can seem conservative but we firmly believe that clients expect us to over-perform rather than disappoint. Ask us, if you want to learn more about the total measurement uncertainty for your specific application.

Applications

• Oil & Gas

- Oil & Gas Storage and Distribution

- Underground Gas Storage & Processing

Technical Facts

| Measurement uncertainty (volumetric flow rate) | ±1...3 % of reading ±0.005 m/s |

| Repeatability | 0.15 % of reading ±0.005 m/s |

| Flow velocity range | 0.01...35 m/s, depending on pipe diameter |

| Ex zone transmitter | ATEX/IECEx Zone 2, FM Class I /Div 2 |

| Power supply | 100-230VAC, 24DC, 12DC |

| Available transducer | Shear wave/Lamb wave |

| for Ex zones | ATEX/IECEx Zone 1/Zone 2 |

| for pipe sizes range | 7mm ... 1600mm |

| for temperature range | -40°C ... +240°C / WI: -200°C ... +600°C |

| Outputs | 4-20mA active/passive |

| Inputs | Pt100/Pt1000 |

| Digital communication | Modbus RTU |

게시물수정

게시물 수정을 위해 비밀번호를 입력해주세요.

댓글삭제게시물삭제

게시물 삭제를 위해 비밀번호를 입력해주세요.