For Liquid

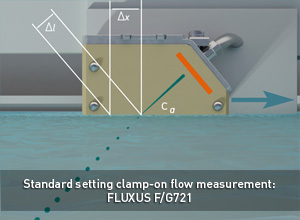

Setting Standards in Clamp-on Ultrasonic Liquid Flow Measurement

The FLUXUS F721 is a technological breakthrough in the ultrasonic clamp-on volume and mass flow measurement of liquids.

With its state-of-the-art hardware design and powerful digital signal processing it surpasses any other non-intrusive ultrasonic flowmeter in terms of accuracy, reliability and versatility.

Highly sophisticated signal filters, faster than ever processing capacities and advanced measurement algorithms make the FLUXUS F721 liquid flow meter the standard setting measuring solution for any industrial application- even for the most challenging ones.

The meter adapts itself automatically to the respective measurement conditions and compensates for flow profile disturbances such as beam dispersal and structure-borne noise, allowing for even more precise and reliable measurements. Extreme fast measurement cycles enable precise real time monitoring of highly dynamic processes.

Pushing the Boundaries

The FLUXUS F721 offers non-intrusive flow measurement of virtually any kind of liquid, from the smallest tubing to the largest penstock, independent of the pressure inside the pipe and over a very large temperature range. Due to its advanced technology, the measurement is unaffected by solid or gaseous entrainments and distinguishes itself by its unrivalled turndown ratio: Even low flows down to only a few liters per hour can be recorded accurately.

Besides its advanced signal processing and evaluation technology, FLEXIM takes special care within the manufacturing process of the flow meter,

Besides its advanced signal processing and evaluation technology, FLEXIM takes special care within the manufacturing process of the flow meter,

ensuring highest precision and reliability. To achieve true zero point stability, FLEXIM carefully matches each ultrasonic transducer pair according

to their individual characteristics. Due to unique transducer built-in temperature probes, the FLUXUS F721 automatically detects and compensates

temperature differentials between pipe and transducer, ruling out measurement drift (ANSI/ASME MFC-5.1.-2011 regulations). Also, every transducer and transmitter is factory calibrated guaranteeing specified accuracies and ensuring highest traceability and flexibility.

Furthermore, the FLUXUS F721 shares all common advantages of our FLUXUS clamp-on flow meters in terms of ease of installation, non-existent

maintenance efforts and unrivalled cost-efficiency. As the flowmeter of choice for a very wide range of applications in virtually any industrial sector,

the FLUXUS F721 is available with two different enclosure types: aluminium for standard applications and stainless steel for operation in hazardous

and highly corrosive environments (ATEX, IECEx Zone 2 and FMc Class I, Div. 2 certified).

Ready for Industry 4.0

The FLUXUS F721 comes with all common communication protocols: HART, Modbus, Foundation Fieldbus, Profibus PA, BACnet and M-Bus allow bidirectional field communication and online diagnostics. The FLUXUS F721 is also one step ahead in terms of user guidance and diagnostics. It can be easily set-up and configured via USB. Its Ethernet connectivity provides additional bidirectional communication capabilities.

Further value is added by the meters advanced selfmonitoring capabilities and the possibility of event driven data recording. The flow meter is permanently controlling the quality of the measurement. Such values, but also every other measurement data as well as externally fed in data, e.g. pressure and temperatues, can be chosen to trigger free defined meter functionalities. For instance, in case the quality of the measurement is falling below a predefined value, a temporary recording of high resolution measurement data can automatically be started. Such free configurable event based trigger functionality is not only perfectly suited for measurement diagnostics, but even more for the accurate monitoring of processes and especially the supervision and control of critical operations.

Applications

• Oil & Gas

- Refinery Solutions

- Onshore / Shale Oil & Gas Solutions

- Underground Gas Storage & Processing

- Upstream / Offshore Solutions

- Oil & Gas Storage and Distribution

• Chemical Industry

- Acid and Caustics Production

- Base & Intermediate Chemicals

- Fertilizer Plants

- Infrastructure and Feedstock Flows

- Polymer Production

- Chlorine Alkali Electrolysis

• Industry Solutions

- Pharmaceutical Industries

- Pulp & Paper

- Mining

- Marine

• Power Industry

- Hydroelectric power plants

Technical Facts

| Measurement uncertainty (volumetric flow rate) | ±1 % of reading ±0.005 m/s |

| Repeatability | 0.15 % of reading ±0.005 m/s |

| Flow velocity range | 0.01...25 m/s |

| Ex zone transmitter | ATEX/IECEx Zone 2, FM Class I /Div 2 |

| Power supply | 100-230VAC, 24DC, 12DC |

| Available transducer | Shear Wave |

| for Ex zones | ATEX/IECEx Zone 1/Zone 2 |

| for pipe sizes range | 6mm ... 6500mm |

| for temperature range | -40°C ... +240°C / WI: -200°C ... +600°C |

| Outputs | 4-20mA active/passive 4-20mA HART active/passive pulse/frequency/binary |

| Inputs | Pt100/Pt1000 4-20mA active/passive Binary input |

| Digital communication | Modbus RTU/TCP BACnet MSTP/IP M-Bus Profibus PA Foundation Fieldbus |

| Additional Information | For more detailed Information please download the Technical Specifications |

게시물수정

게시물 수정을 위해 비밀번호를 입력해주세요.

댓글삭제게시물삭제

게시물 삭제를 위해 비밀번호를 입력해주세요.