For Liquid

14

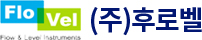

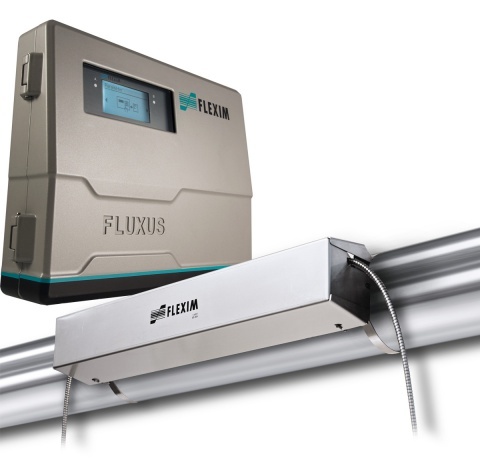

Ultrasonic Standard Volume Flow Meter (FLUXUS H721)

Clamp-on Ultrasonic Standard Volume Flow Measurement and API Determination of Hydrocarbons

FLUXUS H721 is FLEXIM’s flow and analytical measuring system for the hydrocarbon processing industry (HPI). It combines highly precise non-invasive measurement of volume flow and sound speed with sophisticated calculation features. The transmitter’s internal HPI computer calculates API gravity, operational density, density at base conditions and kinematic viscosity. Temperature and pressure compensation according to industry standards such as ASTM1250, GPA TP25 and D4311 allows for precise standard volume flow measurement of liquid hydrocarbons.

FLUXUS H721 is equipped with a database for a wide range of applications from light hydrocarbons to crude oils/refined products to heavy hydrocarbons. Application-specific parameterisation is easily possible via an editable table on the transmitter with liquid names and specific properties (density, API).

Typical applications of FLUXUS H721 are e.g. monitoring of pipeline integrity, product identification in tank farms, quality check measurements and verification or temporary replacement of stationary measuring devices.

Advantages

Cutting-edge Features of FLEXIM's ultrasonic non-intrusive flow measurement

• Automatic Fluid Identification and Interface Detection

• Bi-directional flow metering

• Superior temperature stability - No zero drift

• Certified and traceable Multi-Point wet flow calibration

• Robust “Fit for Purpose” Flexibility and Stability using PERMALOK mounting fixtures

• Operational capabilities from –40 °C up to +200 °C

• Extremely high turndown range - capability of measuring at very low flow rates

Applications

• Oil & Gas

- Oil & Gas Storage and Distribution

• Industry Solutions

- Marine

Technical Facts

Measuring quantities • flow: operating volumetric flow rate, standard volumetric flow rate according to ASTM 1250/TP25/4311, flow velocity, mass flow rate • HPI: API gravity, density, normalised density• interface detection: slope of the HPI physical quantities• fluid detection: according to fluid table Measurement uncertainty

(volumetric flow rate) ±1 % of reading ±0.005 m/s Transit time (HPI functions)repeatable:

1/(50 • fα) ±10-4 • tabsolute:

1/(5 • fα) ±10-4 • t

fα – transducer frequency

t – total transit time e.g. for transducers with transducer frequency M (fα = 1 MHz):

repeatable: 20 ns ±10-4 . t

absolute: 200 ns ±10-4 . t Explosion protectionTransmitter:

ATEX/IECEx zone 2

Transducers:

ATEX/IECEx Zone 2, FM Class I /Div 2 Power supply100 ... 230 V AC / 50 ... 60 Hz

12 / 24 V DC Outputs4 - 20 mA active

4- 20 mA HART active / passive

pulse / frequency / binary InputsPt100 / Pt1000

4 - 20 mA active / passive Digital communicationModbus RTU/TCP

HART

Profibus PA

Foundation Fieldbus Pipe diameter range6 mm ... 6500 mm Temperature range (pipe wall)-40 °C ... +240 °C Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2021.02.04

FLUXUS H721 is FLEXIM’s flow and analytical measuring system for the hydrocarbon processing industry (HPI). It combines highly precise non-invasive measurement of volume flow and sound speed with sophisticated calculation features. The transmitter’s internal HPI computer calculates API gravity, operational density, density at base conditions and kinematic viscosity. Temperature and pressure compensation according to industry standards such as ASTM1250, GPA TP25 and D4311 allows for precise standard volume flow measurement of liquid hydrocarbons.

FLUXUS H721 is equipped with a database for a wide range of applications from light hydrocarbons to crude oils/refined products to heavy hydrocarbons. Application-specific parameterisation is easily possible via an editable table on the transmitter with liquid names and specific properties (density, API).

Typical applications of FLUXUS H721 are e.g. monitoring of pipeline integrity, product identification in tank farms, quality check measurements and verification or temporary replacement of stationary measuring devices.

Advantages

Cutting-edge Features of FLEXIM's ultrasonic non-intrusive flow measurement

• Automatic Fluid Identification and Interface Detection

• Bi-directional flow metering

• Superior temperature stability - No zero drift

• Certified and traceable Multi-Point wet flow calibration

• Robust “Fit for Purpose” Flexibility and Stability using PERMALOK mounting fixtures

• Operational capabilities from –40 °C up to +200 °C

• Extremely high turndown range - capability of measuring at very low flow rates

Applications

• Oil & Gas

- Oil & Gas Storage and Distribution

• Industry Solutions

- Marine

Technical Facts

Measuring quantities • flow: operating volumetric flow rate, standard volumetric flow rate according to ASTM 1250/TP25/4311, flow velocity, mass flow rate • HPI: API gravity, density, normalised density• interface detection: slope of the HPI physical quantities• fluid detection: according to fluid table Measurement uncertainty

(volumetric flow rate) ±1 % of reading ±0.005 m/s Transit time (HPI functions)repeatable:

1/(50 • fα) ±10-4 • tabsolute:

1/(5 • fα) ±10-4 • t

fα – transducer frequency

t – total transit time e.g. for transducers with transducer frequency M (fα = 1 MHz):

repeatable: 20 ns ±10-4 . t

absolute: 200 ns ±10-4 . t Explosion protectionTransmitter:

ATEX/IECEx zone 2

Transducers:

ATEX/IECEx Zone 2, FM Class I /Div 2 Power supply100 ... 230 V AC / 50 ... 60 Hz

12 / 24 V DC Outputs4 - 20 mA active

4- 20 mA HART active / passive

pulse / frequency / binary InputsPt100 / Pt1000

4 - 20 mA active / passive Digital communicationModbus RTU/TCP

HART

Profibus PA

Foundation Fieldbus Pipe diameter range6 mm ... 6500 mm Temperature range (pipe wall)-40 °C ... +240 °C Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2021.02.04

13

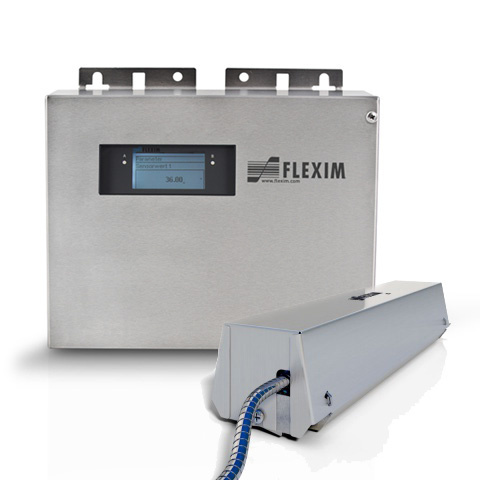

Ultrasonic Flow Meter (FLUXUS SIL F)

Functional Safety with FLUXUS

FLUXUS SIL - Non-invasive Fuctional Safety approved Flowmeter

The FLUXUS non-invasive ultrasonic flow meters have always been the first choice when it comes to maintaining accurate measurements in harsh conditions – e.g. during the flow measurement of aggressive, toxic or highly explosive media, at high temperatures or high pressure.

FLUXUS measures from the safe side: From outside.

The clamp-on ultrasonic transducers are simply mounted on the outside of the pipe. Without any risk of leak and during ongoing operation. The ultrasonic measuring method doesn’t need any wetted devices, does not pose any risk of clogging and is not subjected to mechanical stress which means it is practically wear-free.

As the wetted parts of inline measuring devices are not subject to the Failure Mode Effects and Diagnostics Analysis (FMEDA), they are not included in the scope of certification - presenting a safety risk. On the other hand, the SIL 2 certification of the FLUXUS non-invasive flow meter includes the entire measuring system -the measuring transmitters and transducers. It also includes the patented WaveInjector mounting fixture for extreme temperatures, allowing the non-invasive flow measurement at liquid temperatures from as low as -190 °C up to +650 °C. FLEXIM also offers special radiation-resistant transducers for use in the nuclear industry.

Safety without interruption.

The advantages of FLEXIMs non-invasive flow measurement technology pay off all the more over the entire lifecycle:

There is never any need to interfere with the pipeline system when carrying out periodic inspections. The self-diagnosis functions of the FLUXUS mean retests can be carried out easily to accurately assess the reliability and quality of the measurement. Even more detailed functional tests such as alarm tests or tests for monitoring compliance with measuring accuracy requirements never interfere with plant availability.

Advantages

Functional safety with FLUXUS

• Non-invasive measurement without media contact

- shortened prior-use method

• Simple retrofitting during ongoing operation

- ideal for a subsequent increase in safety

- ideal for maintaining the protective function should an inline measurement fail

• Comprehensive certification

- transducers, clamp device and electronics are part of the FMEDA

• Extremely wide range of applications

- transducers and measuring transmitters for the flow measurement of liquids and gases

- SIL certification also covers WaveInjector technology for the flow measurement of liquids at extreme temperatures of -190 °C to +650 °C

• Straightforward retesting

- easy functional tests in no time at all

- convincing self-diagnosis functions

• Transparent evaluations

- publication of FMEDA report

- full information on certification procedures and scope

Applications

• Chemical Industry

- Base & Intermediate Chemicals

Technical Facts

FLUXUS F70XATEX, IECEx Zone 2, FM Class I, Div. 1 approval (optional), IP66, aluminium or stainless steel housing variants

FLUXUS ADM8X27ATEX, IECEx Zone 1, FM Class I, Div. 1 approval, IP66, aluminium or stainless steel housing variants - suitable for offshore use

Measuring quantitiesvolume flow rate, mass flow rate, flow velocity

Operating temperature of the transmitter-10 °C to +60 °C Degree of protection Transducersup to IP68 Operating temperature of the transducers at pipe wall-40 °C to +200°C or

-190 °C to +650 °C in conjunction with WaveInjector mounting fixture Flow velocity range0,01 to 25 m/s Pipe diameter range6 mm to 6500 mm Measurement accuracy

(extended calibration)± 1,2% of reading ± 0,01 m/s Measurement accuracy

(field calibrated)± 0,5% of reading ± 0,01 m/s Repeatability0,15% of reading ± 0,01 m/s Data logger capacity>100 000 values: all quantities, summed measurings and diagnostics Communication ProtocolModbus RTU Power supply100 to 240 V AC / 50 to 60 Hz or 20 to 32 V DC

관리자 2021.02.04

FLUXUS SIL - Non-invasive Fuctional Safety approved Flowmeter

The FLUXUS non-invasive ultrasonic flow meters have always been the first choice when it comes to maintaining accurate measurements in harsh conditions – e.g. during the flow measurement of aggressive, toxic or highly explosive media, at high temperatures or high pressure.

FLUXUS measures from the safe side: From outside.

The clamp-on ultrasonic transducers are simply mounted on the outside of the pipe. Without any risk of leak and during ongoing operation. The ultrasonic measuring method doesn’t need any wetted devices, does not pose any risk of clogging and is not subjected to mechanical stress which means it is practically wear-free.

As the wetted parts of inline measuring devices are not subject to the Failure Mode Effects and Diagnostics Analysis (FMEDA), they are not included in the scope of certification - presenting a safety risk. On the other hand, the SIL 2 certification of the FLUXUS non-invasive flow meter includes the entire measuring system -the measuring transmitters and transducers. It also includes the patented WaveInjector mounting fixture for extreme temperatures, allowing the non-invasive flow measurement at liquid temperatures from as low as -190 °C up to +650 °C. FLEXIM also offers special radiation-resistant transducers for use in the nuclear industry.

Safety without interruption.

The advantages of FLEXIMs non-invasive flow measurement technology pay off all the more over the entire lifecycle:

There is never any need to interfere with the pipeline system when carrying out periodic inspections. The self-diagnosis functions of the FLUXUS mean retests can be carried out easily to accurately assess the reliability and quality of the measurement. Even more detailed functional tests such as alarm tests or tests for monitoring compliance with measuring accuracy requirements never interfere with plant availability.

Advantages

Functional safety with FLUXUS

• Non-invasive measurement without media contact

- shortened prior-use method

• Simple retrofitting during ongoing operation

- ideal for a subsequent increase in safety

- ideal for maintaining the protective function should an inline measurement fail

• Comprehensive certification

- transducers, clamp device and electronics are part of the FMEDA

• Extremely wide range of applications

- transducers and measuring transmitters for the flow measurement of liquids and gases

- SIL certification also covers WaveInjector technology for the flow measurement of liquids at extreme temperatures of -190 °C to +650 °C

• Straightforward retesting

- easy functional tests in no time at all

- convincing self-diagnosis functions

• Transparent evaluations

- publication of FMEDA report

- full information on certification procedures and scope

Applications

• Chemical Industry

- Base & Intermediate Chemicals

Technical Facts

FLUXUS F70XATEX, IECEx Zone 2, FM Class I, Div. 1 approval (optional), IP66, aluminium or stainless steel housing variants

FLUXUS ADM8X27ATEX, IECEx Zone 1, FM Class I, Div. 1 approval, IP66, aluminium or stainless steel housing variants - suitable for offshore use

Measuring quantitiesvolume flow rate, mass flow rate, flow velocity

Operating temperature of the transmitter-10 °C to +60 °C Degree of protection Transducersup to IP68 Operating temperature of the transducers at pipe wall-40 °C to +200°C or

-190 °C to +650 °C in conjunction with WaveInjector mounting fixture Flow velocity range0,01 to 25 m/s Pipe diameter range6 mm to 6500 mm Measurement accuracy

(extended calibration)± 1,2% of reading ± 0,01 m/s Measurement accuracy

(field calibrated)± 0,5% of reading ± 0,01 m/s Repeatability0,15% of reading ± 0,01 m/s Data logger capacity>100 000 values: all quantities, summed measurings and diagnostics Communication ProtocolModbus RTU Power supply100 to 240 V AC / 50 to 60 Hz or 20 to 32 V DC

관리자 2021.02.04

12

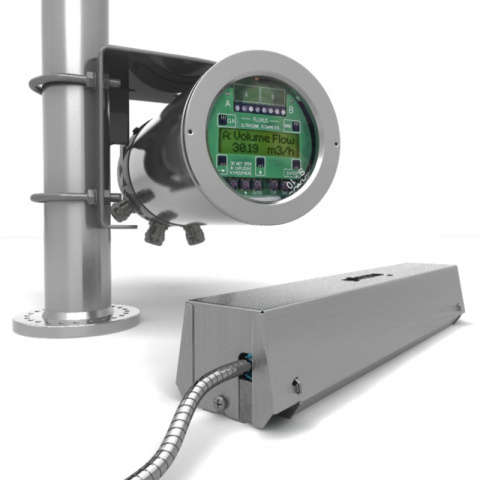

Ultrasonic Flow Meter (FLUXUS XLF)

Non-invasive Flow Meter for Extremely Low Flow rates

Do you need to measure really low flows? Turn to FLUXUS XLF

FLUXUS XLF is FLEXIM‘s non-invasive metering system for the reproducible and long term reliable measurement of extremely low flow rates down to 3 l/h and below on line sizes ranging from 10 mm to 50 mm independent of the pipe wall thickness. As the flow sensors are mounted externally, there is no process interruption for installation.

Moreover, due their IP66 protection degree, ATEX / IECEx Zone 1 / 2 as well as FM Class I, Div. 1 / 2 approval and being completely made out of stainless steel (316L / 1.4404 grade), the measurement system is highly rugged and withstands even the harshest and most corrosive environmental conditions.

FLEXIM is the much more cost-effective and safer alternative for measuring extremely low flows of any liquid

The FLUXUS XLF is applicable on all pipe materials and wall thicknesses as well as independent of operating pressures.

In comparison to wetted instrumentation, the system does not suffer from mechanical stress or wear and tear by the medium and is thus not only much more cost efficient, but also offers significantely higher operational safety as the risk of leaks can completely be eliminated.

Its high accuracy and repeatability at extremely low flow velocities is achieved by carefully matched and temperature compensated transducers (acc. to ANSI/ASME MFC 5.1-2011), highly sensitive electronics and sophisticated internal signal processing as well as a highly precise and traceable wet flow calibration (according to NIST standards) at FLEXIM‘s low flow calibration facility.

Advantages

• No process shut-downs or interruption of supply

• No potential for leaks

• Completely maintenance free

• Accurate and highly repeatable measurement of extremely low flows

• Applicable to any pipe and any liquid media

• Rugged and hazardous area approved transducers and transmitters (ATEX / IECEx Zone 1/2, FM Class I, Div. 1/2)

• Matched transducers, advanced digital signal processing (DSP) and efficient algorithms ensure stable measurements at very low flows

Applications

• Oil & Gas

- Underground Gas Storage & Processing

- Upstream / Offshore Solutions

• Industry Solutions

- Marine

Technical Facts

Flow channels 1 Operating temperature of the transmitter-40 °C ... +60 °C Degree of protectionIP66 Functional Safety (acc. to IEC / DIN EN 61508)SIL2 Optional hazardous area classificationATEX / IECEx Zone 1 and 2, FM Class I, Div. 1 / 2 OutputsA variety of combinations are available from the following: current (0/4 mA ... 20 mA), voltage, frequency, pulse, alarm

InputsMaximum 4, Available are: Temperature (PT 100 4-wire), current, voltage

Communication ProtocolHART or Foundation Fieldbus or ModBus RTU or RS485 or BACNet MS/TP

Media temperature-40 °C ... +200 °C Pipe diameter range10 mm ... 50 mm (independent of material and wall thickness)

Flow velocity range> 0,003 m/sec (at stable media temperatures flows as low as 0,001 m/sec can accurately be monitored)

Calibrated accuracy± 1,2% of reading, ± 0,01 / (N x ID) [m/s] N = number of soundpaths, ID = inner diameter in [inch]

관리자 2021.02.04

Do you need to measure really low flows? Turn to FLUXUS XLF

FLUXUS XLF is FLEXIM‘s non-invasive metering system for the reproducible and long term reliable measurement of extremely low flow rates down to 3 l/h and below on line sizes ranging from 10 mm to 50 mm independent of the pipe wall thickness. As the flow sensors are mounted externally, there is no process interruption for installation.

Moreover, due their IP66 protection degree, ATEX / IECEx Zone 1 / 2 as well as FM Class I, Div. 1 / 2 approval and being completely made out of stainless steel (316L / 1.4404 grade), the measurement system is highly rugged and withstands even the harshest and most corrosive environmental conditions.

FLEXIM is the much more cost-effective and safer alternative for measuring extremely low flows of any liquid

The FLUXUS XLF is applicable on all pipe materials and wall thicknesses as well as independent of operating pressures.

In comparison to wetted instrumentation, the system does not suffer from mechanical stress or wear and tear by the medium and is thus not only much more cost efficient, but also offers significantely higher operational safety as the risk of leaks can completely be eliminated.

Its high accuracy and repeatability at extremely low flow velocities is achieved by carefully matched and temperature compensated transducers (acc. to ANSI/ASME MFC 5.1-2011), highly sensitive electronics and sophisticated internal signal processing as well as a highly precise and traceable wet flow calibration (according to NIST standards) at FLEXIM‘s low flow calibration facility.

Advantages

• No process shut-downs or interruption of supply

• No potential for leaks

• Completely maintenance free

• Accurate and highly repeatable measurement of extremely low flows

• Applicable to any pipe and any liquid media

• Rugged and hazardous area approved transducers and transmitters (ATEX / IECEx Zone 1/2, FM Class I, Div. 1/2)

• Matched transducers, advanced digital signal processing (DSP) and efficient algorithms ensure stable measurements at very low flows

Applications

• Oil & Gas

- Underground Gas Storage & Processing

- Upstream / Offshore Solutions

• Industry Solutions

- Marine

Technical Facts

Flow channels 1 Operating temperature of the transmitter-40 °C ... +60 °C Degree of protectionIP66 Functional Safety (acc. to IEC / DIN EN 61508)SIL2 Optional hazardous area classificationATEX / IECEx Zone 1 and 2, FM Class I, Div. 1 / 2 OutputsA variety of combinations are available from the following: current (0/4 mA ... 20 mA), voltage, frequency, pulse, alarm

InputsMaximum 4, Available are: Temperature (PT 100 4-wire), current, voltage

Communication ProtocolHART or Foundation Fieldbus or ModBus RTU or RS485 or BACNet MS/TP

Media temperature-40 °C ... +200 °C Pipe diameter range10 mm ... 50 mm (independent of material and wall thickness)

Flow velocity range> 0,003 m/sec (at stable media temperatures flows as low as 0,001 m/sec can accurately be monitored)

Calibrated accuracy± 1,2% of reading, ± 0,01 / (N x ID) [m/s] N = number of soundpaths, ID = inner diameter in [inch]

관리자 2021.02.04

11

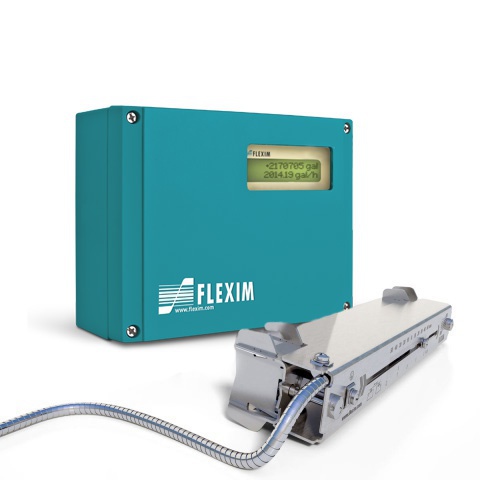

Liquid and Gas Flow Measurement (FLUXUS® F/G721)

Setting Standards in Clamp-on Ultrasonic Liquid Flow Measurement

The FLUXUS F721 is a technological breakthrough in the ultrasonic clamp-on volume and mass flow measurement of liquids.

With its state-of-the-art hardware design and powerful digital signal processing it surpasses any other non-intrusive ultrasonic flowmeter in terms of accuracy, reliability and versatility.

Highly sophisticated signal filters, faster than ever processing capacities and advanced measurement algorithms make the FLUXUS F721 liquid flow meter the standard setting measuring solution for any industrial application- even for the most challenging ones.

The meter adapts itself automatically to the respective measurement conditions and compensates for flow profile disturbances such as beam dispersal and structure-borne noise, allowing for even more precise and reliable measurements. Extreme fast measurement cycles enable precise real time monitoring of highly dynamic processes.

Pushing the Boundaries

The FLUXUS F721 offers non-intrusive flow measurement of virtually any kind of liquid, from the smallest tubing to the largest penstock, independent of the pressure inside the pipe and over a very large temperature range. Due to its advanced technology, the measurement is unaffected by solid or gaseous entrainments and distinguishes itself by its unrivalled turndown ratio: Even low flows down to only a few liters per hour can be recorded accurately.

Besides its advanced signal processing and evaluation technology, FLEXIM takes special care within the manufacturing process of the flow meter, ensuring highest precision and reliability. To achieve true zero point stability, FLEXIM carefully matches each ultrasonic transducer pair according to their individual characteristics. Due to unique transducer built-in temperature probes, the FLUXUS F721 automatically detects and compensates temperature differentials between pipe and transducer, ruling out measurement drift (ANSI/ASME MFC-5.1.-2011 regulations). Also, every transducer and transmitter is factory calibrated guaranteeing specified accuracies and ensuring highest traceability and flexibility.

Furthermore, the FLUXUS F721 shares all common advantages of our FLUXUS clamp-on flow meters in terms of ease of installation, non-existent maintenance efforts and unrivalled cost-efficiency. As the flowmeter of choice for a very wide range of applications in virtually any industrial sector, the FLUXUS F721 is available with two different enclosure types: aluminium for standard applications and stainless steel for operation in hazardous and highly corrosive environments (ATEX, IECEx Zone 2 and FMc Class I, Div. 2 certified).

Ready for Industry 4.0 The FLUXUS F721 comes with all common communication protocols: HART, Modbus, Foundation Fieldbus, Profibus PA, BACnet and M-Bus allow bidirectional field communication and online diagnostics. The FLUXUS F721 is also one step ahead in terms of user guidance and diagnostics. It can be easily set-up and configured via USB. Its Ethernet connectivity provides additional bidirectional communication capabilities.

Further value is added by the meters advanced selfmonitoring capabilities and the possibility of event driven data recording. The flow meter is permanently controlling the quality of the measurement. Such values, but also every other measurement data as well as externally fed in data, e.g. pressure and temperatues, can be chosen to trigger free defined meter functionalities. For instance, in case the quality of the measurement is falling below a predefined value, a temporary recording of high resolution measurement data can automatically be started. Such free configurable event based trigger functionality is not only perfectly suited for measurement diagnostics, but even more for the accurate monitoring of processes and especially the supervision and control of critical operations.

Applications

• Oil & Gas - Refinery Solutions - Onshore / Shale Oil & Gas Solutions - Underground Gas Storage & Processing - Upstream / Offshore Solutions - Oil & Gas Storage and Distribution

• Chemical Industry - Acid and Caustics Production - Base & Intermediate Chemicals - Fertilizer Plants - Infrastructure and Feedstock Flows - Polymer Production - Chlorine Alkali Electrolysis

• Industry Solutions - Pharmaceutical Industries - Pulp & Paper - Mining - Marine

• Power Industry - Hydroelectric power plants

Technical Facts

Measurement uncertainty

(volumetric flow rate) ±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitterATEX/IECEx Zone 2, FM Class I /Div 2 Power supply100-230VAC, 24DC, 12DCAvailable transducer Shear Wave for Ex zonesATEX/IECEx Zone 1/Zone 2

FM Class I - Div2 for pipe sizes range6mm ... 6500mm for temperature range-40°C ... +240°C / WI: -200°C ... +600°C Outputs4-20mA active/passive

4-20mA HART active/passive

pulse/frequency/binary InputsPt100/Pt1000

4-20mA active/passive

Binary input Digital communicationModbus RTU/TCP

BACnet MSTP/IP

M-Bus

Profibus PA

Foundation Fieldbus Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2021.02.04

The FLUXUS F721 is a technological breakthrough in the ultrasonic clamp-on volume and mass flow measurement of liquids.

With its state-of-the-art hardware design and powerful digital signal processing it surpasses any other non-intrusive ultrasonic flowmeter in terms of accuracy, reliability and versatility.

Highly sophisticated signal filters, faster than ever processing capacities and advanced measurement algorithms make the FLUXUS F721 liquid flow meter the standard setting measuring solution for any industrial application- even for the most challenging ones.

The meter adapts itself automatically to the respective measurement conditions and compensates for flow profile disturbances such as beam dispersal and structure-borne noise, allowing for even more precise and reliable measurements. Extreme fast measurement cycles enable precise real time monitoring of highly dynamic processes.

Pushing the Boundaries

The FLUXUS F721 offers non-intrusive flow measurement of virtually any kind of liquid, from the smallest tubing to the largest penstock, independent of the pressure inside the pipe and over a very large temperature range. Due to its advanced technology, the measurement is unaffected by solid or gaseous entrainments and distinguishes itself by its unrivalled turndown ratio: Even low flows down to only a few liters per hour can be recorded accurately.

Besides its advanced signal processing and evaluation technology, FLEXIM takes special care within the manufacturing process of the flow meter, ensuring highest precision and reliability. To achieve true zero point stability, FLEXIM carefully matches each ultrasonic transducer pair according to their individual characteristics. Due to unique transducer built-in temperature probes, the FLUXUS F721 automatically detects and compensates temperature differentials between pipe and transducer, ruling out measurement drift (ANSI/ASME MFC-5.1.-2011 regulations). Also, every transducer and transmitter is factory calibrated guaranteeing specified accuracies and ensuring highest traceability and flexibility.

Furthermore, the FLUXUS F721 shares all common advantages of our FLUXUS clamp-on flow meters in terms of ease of installation, non-existent maintenance efforts and unrivalled cost-efficiency. As the flowmeter of choice for a very wide range of applications in virtually any industrial sector, the FLUXUS F721 is available with two different enclosure types: aluminium for standard applications and stainless steel for operation in hazardous and highly corrosive environments (ATEX, IECEx Zone 2 and FMc Class I, Div. 2 certified).

Ready for Industry 4.0 The FLUXUS F721 comes with all common communication protocols: HART, Modbus, Foundation Fieldbus, Profibus PA, BACnet and M-Bus allow bidirectional field communication and online diagnostics. The FLUXUS F721 is also one step ahead in terms of user guidance and diagnostics. It can be easily set-up and configured via USB. Its Ethernet connectivity provides additional bidirectional communication capabilities.

Further value is added by the meters advanced selfmonitoring capabilities and the possibility of event driven data recording. The flow meter is permanently controlling the quality of the measurement. Such values, but also every other measurement data as well as externally fed in data, e.g. pressure and temperatues, can be chosen to trigger free defined meter functionalities. For instance, in case the quality of the measurement is falling below a predefined value, a temporary recording of high resolution measurement data can automatically be started. Such free configurable event based trigger functionality is not only perfectly suited for measurement diagnostics, but even more for the accurate monitoring of processes and especially the supervision and control of critical operations.

Applications

• Oil & Gas - Refinery Solutions - Onshore / Shale Oil & Gas Solutions - Underground Gas Storage & Processing - Upstream / Offshore Solutions - Oil & Gas Storage and Distribution

• Chemical Industry - Acid and Caustics Production - Base & Intermediate Chemicals - Fertilizer Plants - Infrastructure and Feedstock Flows - Polymer Production - Chlorine Alkali Electrolysis

• Industry Solutions - Pharmaceutical Industries - Pulp & Paper - Mining - Marine

• Power Industry - Hydroelectric power plants

Technical Facts

Measurement uncertainty

(volumetric flow rate) ±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitterATEX/IECEx Zone 2, FM Class I /Div 2 Power supply100-230VAC, 24DC, 12DCAvailable transducer Shear Wave for Ex zonesATEX/IECEx Zone 1/Zone 2

FM Class I - Div2 for pipe sizes range6mm ... 6500mm for temperature range-40°C ... +240°C / WI: -200°C ... +600°C Outputs4-20mA active/passive

4-20mA HART active/passive

pulse/frequency/binary InputsPt100/Pt1000

4-20mA active/passive

Binary input Digital communicationModbus RTU/TCP

BACnet MSTP/IP

M-Bus

Profibus PA

Foundation Fieldbus Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2021.02.04

10

Ultrasonic Flow Meter (PIOX R721)

Inline Process Refractometer PIOX R721 – Chemical Design Variant

The concentration analysis of liquid media is one of the most critical parameters for a proper process and quality control within the Chemical Industry.

By measuring the refractive index, concentration levels of many media consumed or created within the chemical and textile fiber industry, such as solvents, acids, caustics as well as other intermediate and end products, can accurately be monitored and a continuous quality control be assured.

The chemical design variant of the process refractometer PIOX R721 R is offered as a fully stainless steel design variant with all wetted materials made out of grade 316 Ti / 1.4571 steel.

When dealing with highly corrosive media, such as hydrochloric, strong sulfuric or hydroflouric acid, PIOX R is also available as a special carbon reinforced PTFE design variant offering an unrivalled corrosion resistance, long term stability and reliability in such harsh environments.

Both designs are highly durable against any corrosive and toxic media due to their internal FFKM gaskets, the media and scratch resistant sapphire optics as well as the complete separation of the sensorhead from the electronics compartment.

Being ATEX Zone 0/1 certified and available with long and short sensorheads that can be integrated into the process via DIN / ANSI flange or the proprietary FLEXIM flow cell, PIOX R721 is the ideal process analytical technology for a wide array of liquid media within the chemical industry.

Advantages

• Patented transmitted light measurement principle - offering completely drift free, precise and long term stable measurements

• Highly accurate optical process technology making costly laboratory tests obsolete

• No flow velocity needed - as known from conventional technologies

• Independent in regard to gas bubbles and turbidity as well as the media‘s viscosity

• Internal self diagnostic tools for predictive and low maintenance efforts

Advantages

• Oil & Gas

- Underground Gas Storage & Processing

- Upstream / Offshore Solutions

• Chemical Industry

- Base & Intermediate Chemicals

- Polymer Production

• Industry Solutions

- Pulp & Paper

- Semiconductor Industries

Technical Facts

Measuring quantitiesRefractive index and refractive index at standard temperature, fluid temperature, concentration g/l, mass and vol.%, density and density at standard temperature, scale values for example °Brix and °API, additional quantities programmable

Measurement rangenD: 1.3 ...1.7, °Brix: 0 ...100 Measurement accuracynD: 0.0002 (corresponds to: 0.1 °Brix, 0.1 w%) RepeatabilitynD: 0.00002 (corresponds to: 0.01 °Brix, 0.01 w%) Operating temp. (media)- 20 °C ... (+ 130 °C) + 150 °C Fluid pressurePN 10, PN 16, on request PN 40 (depending on process connection)

Degree of protectionSensor R500: IP67, ATEX (IECEx) zone 0,1,2

Transmitter R721: aluminium or stainless steel enclosure, IP66, ATEX (IECEx) zone 2

Wetted parts, materialsStainless steel 316Ti (1.4571) Housing materialStainless steel 304 (1.4301) Process connectionDIN/ANSI flange, sight glass fitting, proprietary FLEXIM flow cell Additional NotesPTFE Chemical Design variant: Wetted parts, materials: PTFE carbon-fiber reinforced bulk material

관리자 2020.06.08

The concentration analysis of liquid media is one of the most critical parameters for a proper process and quality control within the Chemical Industry.

By measuring the refractive index, concentration levels of many media consumed or created within the chemical and textile fiber industry, such as solvents, acids, caustics as well as other intermediate and end products, can accurately be monitored and a continuous quality control be assured.

The chemical design variant of the process refractometer PIOX R721 R is offered as a fully stainless steel design variant with all wetted materials made out of grade 316 Ti / 1.4571 steel.

When dealing with highly corrosive media, such as hydrochloric, strong sulfuric or hydroflouric acid, PIOX R is also available as a special carbon reinforced PTFE design variant offering an unrivalled corrosion resistance, long term stability and reliability in such harsh environments.

Both designs are highly durable against any corrosive and toxic media due to their internal FFKM gaskets, the media and scratch resistant sapphire optics as well as the complete separation of the sensorhead from the electronics compartment.

Being ATEX Zone 0/1 certified and available with long and short sensorheads that can be integrated into the process via DIN / ANSI flange or the proprietary FLEXIM flow cell, PIOX R721 is the ideal process analytical technology for a wide array of liquid media within the chemical industry.

Advantages

• Patented transmitted light measurement principle - offering completely drift free, precise and long term stable measurements

• Highly accurate optical process technology making costly laboratory tests obsolete

• No flow velocity needed - as known from conventional technologies

• Independent in regard to gas bubbles and turbidity as well as the media‘s viscosity

• Internal self diagnostic tools for predictive and low maintenance efforts

Advantages

• Oil & Gas

- Underground Gas Storage & Processing

- Upstream / Offshore Solutions

• Chemical Industry

- Base & Intermediate Chemicals

- Polymer Production

• Industry Solutions

- Pulp & Paper

- Semiconductor Industries

Technical Facts

Measuring quantitiesRefractive index and refractive index at standard temperature, fluid temperature, concentration g/l, mass and vol.%, density and density at standard temperature, scale values for example °Brix and °API, additional quantities programmable

Measurement rangenD: 1.3 ...1.7, °Brix: 0 ...100 Measurement accuracynD: 0.0002 (corresponds to: 0.1 °Brix, 0.1 w%) RepeatabilitynD: 0.00002 (corresponds to: 0.01 °Brix, 0.01 w%) Operating temp. (media)- 20 °C ... (+ 130 °C) + 150 °C Fluid pressurePN 10, PN 16, on request PN 40 (depending on process connection)

Degree of protectionSensor R500: IP67, ATEX (IECEx) zone 0,1,2

Transmitter R721: aluminium or stainless steel enclosure, IP66, ATEX (IECEx) zone 2

Wetted parts, materialsStainless steel 316Ti (1.4571) Housing materialStainless steel 304 (1.4301) Process connectionDIN/ANSI flange, sight glass fitting, proprietary FLEXIM flow cell Additional NotesPTFE Chemical Design variant: Wetted parts, materials: PTFE carbon-fiber reinforced bulk material

관리자 2020.06.08

9

Ultrasonic Flow Meter (FLUXUS F801)

The Offshore Flow Meter for liquids

The ultrasonic flow meter for Offshore and Mining applications

The FLUXUS F801 flow meter for liquids is FLEXIM's solution for explosion hazard environments Offshore (being ATEX (IECEx) approved for usage in zones 1 and 2).

With a flameproof field-enclosure made entirely of stainless steel, the flow meter is permanently sea spray and seawater proof and can easily be operated by a magnet pen without having to open the housing.

The FLUXUS F801 flow meter allows for an inherently bi-directional flow measurement of volume and mass flow rates of nearly any liquid media - ranging from crude oil to refined products - and can be equipped with various outputs to be used for a sophisticated process control. As the ultrasonic transducers are mounted on the outside of the pipe wall, enclosed in the rugged stainless steel VARIOFIX C mounting fixture, the system does not suffer from wear, tear or clogging and can't be a risk for leaks.

Due to it's matched and paired transducers as well as the internal temperature compensation (compliant to ANSI/ASME regulations), the measurement system is drift free and zero stable. Moreover, as the transducers calibration data is automatically loaded by connecting the transducer to the transmitter, set-up times are significantly reduced. As of its exceptional dual-uP technology, the high number of measuring cycles per second and the adaptive signal processing, the FLUXUSF801 flow meter produces stable and reliable measuring results even under the most difficult conditions.

The F801 flow meter can be applied at inner pipe diameters ranging from 10 mm up to 6500 mm (no limitations on pipe wall thickness or material) and media temperatures from -170 °C up to +600 °C (by usage of the high temperature mounting fixture WaveInjector).

With up to two measurement channels, the FLUXUS F801 flow meter can also be applied to difficult measurement points with non-ideal flow profiles. Even liquid streams with a high content of solids or gas bubbles are not a problem due to the innovative HybridTrek mode implemented into the flow computer.

Advantages• Ultrasonic clamp-on flow meter with two measurement channels and ATEX Zone 1 approval

• Rugged seawater resistant SS316 Stainless Steel flameproof housing

• Installation and parameterization without having to open the housing

• Installation without process shut-down

• Very cost efficient measurement system - virtually no maintenance needed

• Stable, accurate and reliable measurement readings due to matched and temperature compensated transducers as well as innovative digital signal processing

• Independent of entrained particles or gas bubbles

• Flexible configurable outputs

• Measurement at any pipe material, size, wall thickness and at temperatures from -170°C up to 400°C and beyond (with WaveInjector mounting fixture)

• Independent of pressurization inside the pipe

Applications

• Oil & Gas

- Upstream / Offshore Solutions

Technical Facts

Measurement uncertainty

(volumetric flow rate)±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitterATEX/IECEx Zone 1 Power supply100-230VAC, 24DC Available transducerShear Wave for Ex zonesATEX/IECEx Zone 1 for pipe sizes range10mm ... 6500mm for temperature range-40°C ... +240°C / WI: -200°C ... +600°C Outputs4-20mA active/passive

4-20mA HART active/passive

4-20mA passive intrinsic safety

pulse/frequency/binary Inputs--- Digital communicationModbus RTU Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2020.06.08

The ultrasonic flow meter for Offshore and Mining applications

The FLUXUS F801 flow meter for liquids is FLEXIM's solution for explosion hazard environments Offshore (being ATEX (IECEx) approved for usage in zones 1 and 2).

With a flameproof field-enclosure made entirely of stainless steel, the flow meter is permanently sea spray and seawater proof and can easily be operated by a magnet pen without having to open the housing.

The FLUXUS F801 flow meter allows for an inherently bi-directional flow measurement of volume and mass flow rates of nearly any liquid media - ranging from crude oil to refined products - and can be equipped with various outputs to be used for a sophisticated process control. As the ultrasonic transducers are mounted on the outside of the pipe wall, enclosed in the rugged stainless steel VARIOFIX C mounting fixture, the system does not suffer from wear, tear or clogging and can't be a risk for leaks.

Due to it's matched and paired transducers as well as the internal temperature compensation (compliant to ANSI/ASME regulations), the measurement system is drift free and zero stable. Moreover, as the transducers calibration data is automatically loaded by connecting the transducer to the transmitter, set-up times are significantly reduced. As of its exceptional dual-uP technology, the high number of measuring cycles per second and the adaptive signal processing, the FLUXUSF801 flow meter produces stable and reliable measuring results even under the most difficult conditions.

The F801 flow meter can be applied at inner pipe diameters ranging from 10 mm up to 6500 mm (no limitations on pipe wall thickness or material) and media temperatures from -170 °C up to +600 °C (by usage of the high temperature mounting fixture WaveInjector).

With up to two measurement channels, the FLUXUS F801 flow meter can also be applied to difficult measurement points with non-ideal flow profiles. Even liquid streams with a high content of solids or gas bubbles are not a problem due to the innovative HybridTrek mode implemented into the flow computer.

Advantages• Ultrasonic clamp-on flow meter with two measurement channels and ATEX Zone 1 approval

• Rugged seawater resistant SS316 Stainless Steel flameproof housing

• Installation and parameterization without having to open the housing

• Installation without process shut-down

• Very cost efficient measurement system - virtually no maintenance needed

• Stable, accurate and reliable measurement readings due to matched and temperature compensated transducers as well as innovative digital signal processing

• Independent of entrained particles or gas bubbles

• Flexible configurable outputs

• Measurement at any pipe material, size, wall thickness and at temperatures from -170°C up to 400°C and beyond (with WaveInjector mounting fixture)

• Independent of pressurization inside the pipe

Applications

• Oil & Gas

- Upstream / Offshore Solutions

Technical Facts

Measurement uncertainty

(volumetric flow rate)±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitterATEX/IECEx Zone 1 Power supply100-230VAC, 24DC Available transducerShear Wave for Ex zonesATEX/IECEx Zone 1 for pipe sizes range10mm ... 6500mm for temperature range-40°C ... +240°C / WI: -200°C ... +600°C Outputs4-20mA active/passive

4-20mA HART active/passive

4-20mA passive intrinsic safety

pulse/frequency/binary Inputs--- Digital communicationModbus RTU Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2020.06.08

8

Ultrasonic Flow Meter (FLUXUS F706)

4-Beams for Precision, Reliability and Repeatability

The FLUXUS F706 combines highest precision with the advantages of non-invasive ultrasonic liquid flow measurement.

With its 4 beams, in reflect mode providing 8 paths through the gaseous medium, the meter averages the result of up to 4 planes. This arrangement averages out cross-flow profile disturbances and achieves the optimum non-invasive compensation. On longer straight runs, the 4-Beam flow meter achieves outstanding accuracy performance due to the individually averaged path effects and can thus be used for redundancy measurements of custody transfer meters or leak detection.

Temperature compensated transducers, unique digital signal processing with superior noise suppression combined with a highly rugged design care for an unrivalled degree of reliabilialy, durability and accuracy - ensuring perfect operation of the system under the harshest field conditions and makes it even suitable for installations buried in the ground (IP68 / NEMA 6P rated).

Custody Transfer Accuracy

The F706 is capable of accuracy in the Custody Transfer class. By measurement principle, non-invasive ultrasonic flow meters will contain some uncertainty due to uncertainties in the pipe wall thickness and pipe geometry. These can be minimized with careful installation, precise pipe wall measurements and especially based on the effects of the multiple 4-channel measurement of the F706. While an installed “out of box” custody transfer accuracy is not possible, in many pipeline services like check-metering, leak detection and others, it is possible to calibrate the F706 meter in-situ to achieve Custody class accuracy (proven by industry independent Calibration Facilities - test reports are available upon request).

AdvantagesEasy installation without process outagesWhen creating a new flow measurement point, a significant part of the costs are incurred by the installation work (line shut-down, pipe cutting, pipe flushing, etc.). These costs are significantly reduced using the F706 clamp-on technology that requires zero impact on pipe integrity while commissioning.

• Highly Economical: No heavy equipment necessary for installation, thus being the ideal solution for remote locations, or poorly accessible areas.• 100% plant availability: The non-invasive measurement technology does not require any process shut-downs - neither for installation nor for any potential maintenance efforts• Extremely low maintenance – virtually zero maintenance due to use of solid couplant pads instead of high maintenance gels• Safety: The F706 clamp-on meter does not add any leakage risk. It also does not require any flanges or gaskest

Laboratory Accuracy under Field ConditionsHigh accuracy and proven laboratory performance under reference conditions is one task. Accuracy under field conditions is quite another thing:

• FLEXIM‘s transducers automatically compensate for ambient temperature changes – according to ANSI/ASME MFC-5.1-2011. This ensures no false measurement readings during temperature swings (day / night)• FLEXIM‘s transducers are carefully paired according to their individual properties. This process lays the foundation for superior accuracies over a wide temperature and application range. It also ensures a negligible zero offset and facilitates the measurement of very low flow rates. There is no need for zeroing, or programmed “automatic zero” workarounds.• FLEXIM‘s transducers are all individually factory calibrated, with storage of the calibration data on a “Sensprom”chip. The calibrated transmitter automatically reads the individual calibration data, avoiding potential errors and making transducer exchanges easy.

For FLEXIM, accuracy is a topic we take seriously. FLEXIM‘s specified installed-accuracy claims can seem conservative but we firmly believe that clients expect us to over-perform rather than disappoint. Ask us, if you want to learn more about the total measurement uncertainty for your specific application.

Applications

• Oil & Gas

- Oil & Gas Storage and Distribution

• Industry Solutions

- Marine

• Power Industry

- Hydroelectric power plants

Technical Facts

Measurement uncertainty

(volumetric flow rate)±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitterATEX/IECEx Zone 2, FM Class I /Div 2 Power supply100-230VAC, 24DC, 12DC Available transducerShear Wave for Ex zonesATEX/IECEx Zone 1/Zone 2

FM Class I - Div2 for pipe sizes range6mm ... 6500mm for temperature range-40°C ... +240°C / WI: -200°C ... +600°C Outputs4-20mA active/passive

4-20mA HART active/passive

pulse/frequency/binary InputsPt100/Pt1000

4-20mA active/passive

Binary input Digital communicationModbus RTU

Foundation Fieldbus

관리자 2020.06.08

The FLUXUS F706 combines highest precision with the advantages of non-invasive ultrasonic liquid flow measurement.

With its 4 beams, in reflect mode providing 8 paths through the gaseous medium, the meter averages the result of up to 4 planes. This arrangement averages out cross-flow profile disturbances and achieves the optimum non-invasive compensation. On longer straight runs, the 4-Beam flow meter achieves outstanding accuracy performance due to the individually averaged path effects and can thus be used for redundancy measurements of custody transfer meters or leak detection.

Temperature compensated transducers, unique digital signal processing with superior noise suppression combined with a highly rugged design care for an unrivalled degree of reliabilialy, durability and accuracy - ensuring perfect operation of the system under the harshest field conditions and makes it even suitable for installations buried in the ground (IP68 / NEMA 6P rated).

Custody Transfer Accuracy

The F706 is capable of accuracy in the Custody Transfer class. By measurement principle, non-invasive ultrasonic flow meters will contain some uncertainty due to uncertainties in the pipe wall thickness and pipe geometry. These can be minimized with careful installation, precise pipe wall measurements and especially based on the effects of the multiple 4-channel measurement of the F706. While an installed “out of box” custody transfer accuracy is not possible, in many pipeline services like check-metering, leak detection and others, it is possible to calibrate the F706 meter in-situ to achieve Custody class accuracy (proven by industry independent Calibration Facilities - test reports are available upon request).

AdvantagesEasy installation without process outagesWhen creating a new flow measurement point, a significant part of the costs are incurred by the installation work (line shut-down, pipe cutting, pipe flushing, etc.). These costs are significantly reduced using the F706 clamp-on technology that requires zero impact on pipe integrity while commissioning.

• Highly Economical: No heavy equipment necessary for installation, thus being the ideal solution for remote locations, or poorly accessible areas.• 100% plant availability: The non-invasive measurement technology does not require any process shut-downs - neither for installation nor for any potential maintenance efforts• Extremely low maintenance – virtually zero maintenance due to use of solid couplant pads instead of high maintenance gels• Safety: The F706 clamp-on meter does not add any leakage risk. It also does not require any flanges or gaskest

Laboratory Accuracy under Field ConditionsHigh accuracy and proven laboratory performance under reference conditions is one task. Accuracy under field conditions is quite another thing:

• FLEXIM‘s transducers automatically compensate for ambient temperature changes – according to ANSI/ASME MFC-5.1-2011. This ensures no false measurement readings during temperature swings (day / night)• FLEXIM‘s transducers are carefully paired according to their individual properties. This process lays the foundation for superior accuracies over a wide temperature and application range. It also ensures a negligible zero offset and facilitates the measurement of very low flow rates. There is no need for zeroing, or programmed “automatic zero” workarounds.• FLEXIM‘s transducers are all individually factory calibrated, with storage of the calibration data on a “Sensprom”chip. The calibrated transmitter automatically reads the individual calibration data, avoiding potential errors and making transducer exchanges easy.

For FLEXIM, accuracy is a topic we take seriously. FLEXIM‘s specified installed-accuracy claims can seem conservative but we firmly believe that clients expect us to over-perform rather than disappoint. Ask us, if you want to learn more about the total measurement uncertainty for your specific application.

Applications

• Oil & Gas

- Oil & Gas Storage and Distribution

• Industry Solutions

- Marine

• Power Industry

- Hydroelectric power plants

Technical Facts

Measurement uncertainty

(volumetric flow rate)±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitterATEX/IECEx Zone 2, FM Class I /Div 2 Power supply100-230VAC, 24DC, 12DC Available transducerShear Wave for Ex zonesATEX/IECEx Zone 1/Zone 2

FM Class I - Div2 for pipe sizes range6mm ... 6500mm for temperature range-40°C ... +240°C / WI: -200°C ... +600°C Outputs4-20mA active/passive

4-20mA HART active/passive

pulse/frequency/binary InputsPt100/Pt1000

4-20mA active/passive

Binary input Digital communicationModbus RTU

Foundation Fieldbus

관리자 2020.06.08

7

Ultrasonic Flow Meter (FLUXUS F502 TE)

Non-Invasive Heat and Cold Metering

Non-Invasive Thermal Energy Metering

The FLUXUS F502 Thermal Energy is specially designed for heat and cold quantity metering in buildings and within the manufacturing industry.

Like all measuring systems of the FLUXUS series, the F502 Thermal Energy measures the volumetric flow rate non-invasively via its clamp-on ultrasonic transducers. Simultaneously temperature probes monitor the temperatures at the supply and return lines of the heating or cooling system - either non-invasively with clamp-on technology or by use of wetted temperature probes.

From the temperature difference as well as the measured volume flow rate and on the basis of the physical media parameters stored in the internal database of the transmitter, the heating or cooling performance is calculated. With the help of the built-in totalizer function the FLUXUS F502 Thermal Energy can also be used as an energy meter. The integrated Modbus RTU, BACnet MS / TP or M-Bus communication interfaces provide for data exchange with the building automation system.

Both the ultrasonic transducers and temperature probes are carefully paired and matched by FLEXIM. Due to these processes, the system measures with a high degree of accuracy and repeatability - even in applications with only small temperature differences, such as in cooling water circuits.

An important advantage of FLUXUS F502 Thermal Energy lies within its high zero point stability and unrivalled accuracy even at very low flow rates - signal drift and significant measurement uncertainty, as it can often be observed at magnetive-inductive heat quantity meters when measuring at low flow rates, can be ruled out. Moreover, even potential mineral deposits on the inner pipe wall cannot influence the measurement.

Thus, the FLUXUS F502 Thermal Energy offers the best metrological basis in terms of precision, long-life time, maintenance-free as well as cost-effective monitoring of thermal energy flows in buildings and manufacturing plants and thus forms the foundation for further process optimization tasks within the scope of a holistic energy management system - e.g. according to DIN ISO 50001.

Advantages

• Reliable and wearfree measurement from outside

• Accurate thermal energy measurement due to:

- highly accurate flow measurement with paired and traceable calibrated ultrasonic transducers - highly accurate temperature measurement with paired and traceable calibrated temperature sensors (acc. to DIN EN 1434-1)

• Extremely high measuring dynamics from the lowest to the highest flow velocities - captures even the slightest flows during night time

• Simple, cost-effective retrofitting without any disruption to supply

• Tamper-proof storage of measuring data

Applications

• Industrial and Municipal Energy Management

- Buildings Cold and Heat Metering - District Heat Metering - Industrial Energy Efficiency

Technical Facts

Measurement uncertainty

(volumetric flow rate) ±1.5 % v. MW ±0.01 m/s Repeatability0.25 % v. MW ±0.01 m/s Flow velocity range0.01...25 m/s Ex zone transmitteronly safe area Power supply230VAC, 12/24VDC Available transducerShearwave for Ex zones--- for pipe sizes rangeDN25 ... DN500 for temperature range-40°C ... 130°C Outputs2x 4-20mA active

2x pulse/binary Inputs2x Pt100/Pt1000 Digital communicationModbus RTU

BACnet MS/TP

M-Bus

관리자 2020.06.08

Non-Invasive Thermal Energy Metering

The FLUXUS F502 Thermal Energy is specially designed for heat and cold quantity metering in buildings and within the manufacturing industry.

Like all measuring systems of the FLUXUS series, the F502 Thermal Energy measures the volumetric flow rate non-invasively via its clamp-on ultrasonic transducers. Simultaneously temperature probes monitor the temperatures at the supply and return lines of the heating or cooling system - either non-invasively with clamp-on technology or by use of wetted temperature probes.

From the temperature difference as well as the measured volume flow rate and on the basis of the physical media parameters stored in the internal database of the transmitter, the heating or cooling performance is calculated. With the help of the built-in totalizer function the FLUXUS F502 Thermal Energy can also be used as an energy meter. The integrated Modbus RTU, BACnet MS / TP or M-Bus communication interfaces provide for data exchange with the building automation system.

Both the ultrasonic transducers and temperature probes are carefully paired and matched by FLEXIM. Due to these processes, the system measures with a high degree of accuracy and repeatability - even in applications with only small temperature differences, such as in cooling water circuits.

An important advantage of FLUXUS F502 Thermal Energy lies within its high zero point stability and unrivalled accuracy even at very low flow rates - signal drift and significant measurement uncertainty, as it can often be observed at magnetive-inductive heat quantity meters when measuring at low flow rates, can be ruled out. Moreover, even potential mineral deposits on the inner pipe wall cannot influence the measurement.

Thus, the FLUXUS F502 Thermal Energy offers the best metrological basis in terms of precision, long-life time, maintenance-free as well as cost-effective monitoring of thermal energy flows in buildings and manufacturing plants and thus forms the foundation for further process optimization tasks within the scope of a holistic energy management system - e.g. according to DIN ISO 50001.

Advantages

• Reliable and wearfree measurement from outside

• Accurate thermal energy measurement due to:

- highly accurate flow measurement with paired and traceable calibrated ultrasonic transducers - highly accurate temperature measurement with paired and traceable calibrated temperature sensors (acc. to DIN EN 1434-1)

• Extremely high measuring dynamics from the lowest to the highest flow velocities - captures even the slightest flows during night time

• Simple, cost-effective retrofitting without any disruption to supply

• Tamper-proof storage of measuring data

Applications

• Industrial and Municipal Energy Management

- Buildings Cold and Heat Metering - District Heat Metering - Industrial Energy Efficiency

Technical Facts

Measurement uncertainty

(volumetric flow rate) ±1.5 % v. MW ±0.01 m/s Repeatability0.25 % v. MW ±0.01 m/s Flow velocity range0.01...25 m/s Ex zone transmitteronly safe area Power supply230VAC, 12/24VDC Available transducerShearwave for Ex zones--- for pipe sizes rangeDN25 ... DN500 for temperature range-40°C ... 130°C Outputs2x 4-20mA active

2x pulse/binary Inputs2x Pt100/Pt1000 Digital communicationModbus RTU

BACnet MS/TP

M-Bus

관리자 2020.06.08

6

Ultrasonic Flow Meter (FLUXUS WD)

Stationary Ultrasonic Water Flow Meter

The FLUXUS WD Series non-invasive ultrasonic flow meter is the ideal solution for metering points in the drinking water network.

Due to the use of its clamp-on technology, the WD Series that does not require any work that affects the integrity of the pipe. This enables a very simple and cost-effective installation of flow measurement points within an existing water supply network.

The FLUXUS WD Series belongs to the most reliable and accurate non-invasive ultrasonic flow metering systems - it even measures flow rates as low as 0.01 m/s. The inaccuracy of other meter technologies, such as magnetive inductive meters, can increase so dramatically in the low flow range, that they are unsuitable for monitoring minimum night flows. But for water suppliers the precise monitoring of minimum night flows is an essential part of their leakage detection activities – and the WD Series is the ideal tool for this task.

There is no method of zero drift correction for our instruments – because they just don’t drift. This also applies to the WD Series that is installed without zero calibration and remains drift-free, permanently. FLEXIM is the only company that accomplishes this, thanks to its unique combination of matched piezo-transducers and advanced factory calibration.

FLEXIM supplies the WD Series with the most robust mounting system on the market. The transducers are fixed to the pipe with broad stainless steel straps and secured in robust stainless steel housings. The transducers themselves have IP68 protection and reinforced transducer cables. A further unique feature of FLEXIM is that the transducers are connected with permanent coupling pads, instead of coupling gel that can deteriorate or be washed away. All this ensures the durability of the system and makes it suitable for both installations in chambers and buried installations.

The WD meter is available with three transducer types and is suitable for inner diameters ranging from 50 ... 6500 mm. The strong signal output and noise suppression technology make it possible to use the WD Series on all pipe materials, even on such challenging ones as fiber-reinforced plastic (FRP) pipes. The outstanding performance of FLEXIM is shown by thousands of references worldwide.

Advantages

• Very low installation costs and zero pipe interference

• Extremely accurate down to flow velocities as low as 0.01 m/s

• No zero calibration needed and permanently drift-free

• Permanent coupling pads

• IP68 transducers

• Transducers can be permanently buried (no chamber required)

• Drift-free measurements

• Reliable and accurate data

• Low installation costs

• Built to last

• Works on difficult pipes

Applications

• Water & Sewage

- Potable Water Treatment

- Water network monitoring and leak detection

- Wastewater Treatment

Technical Facts

Measurement uncertainty

(volumetric flow rate) ±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitteronly safe area Power supply100-230VAC, 24DC, 12DC Available transducerShear Wave for Ex zones--- for pipe sizes range50mm ... 6500mm for temperature range-40°C ... +130°C Outputs4-20mA active/passive

4-20mA HART active/passive

pulse/frequency/binaryInputs--- Digital communicationModbus RTU/TCP

BACnet MSTP/IP

M-Bus

Profibus PA

Foundation Fieldbus Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2020.06.08

The FLUXUS WD Series non-invasive ultrasonic flow meter is the ideal solution for metering points in the drinking water network.

Due to the use of its clamp-on technology, the WD Series that does not require any work that affects the integrity of the pipe. This enables a very simple and cost-effective installation of flow measurement points within an existing water supply network.

The FLUXUS WD Series belongs to the most reliable and accurate non-invasive ultrasonic flow metering systems - it even measures flow rates as low as 0.01 m/s. The inaccuracy of other meter technologies, such as magnetive inductive meters, can increase so dramatically in the low flow range, that they are unsuitable for monitoring minimum night flows. But for water suppliers the precise monitoring of minimum night flows is an essential part of their leakage detection activities – and the WD Series is the ideal tool for this task.

There is no method of zero drift correction for our instruments – because they just don’t drift. This also applies to the WD Series that is installed without zero calibration and remains drift-free, permanently. FLEXIM is the only company that accomplishes this, thanks to its unique combination of matched piezo-transducers and advanced factory calibration.

FLEXIM supplies the WD Series with the most robust mounting system on the market. The transducers are fixed to the pipe with broad stainless steel straps and secured in robust stainless steel housings. The transducers themselves have IP68 protection and reinforced transducer cables. A further unique feature of FLEXIM is that the transducers are connected with permanent coupling pads, instead of coupling gel that can deteriorate or be washed away. All this ensures the durability of the system and makes it suitable for both installations in chambers and buried installations.

The WD meter is available with three transducer types and is suitable for inner diameters ranging from 50 ... 6500 mm. The strong signal output and noise suppression technology make it possible to use the WD Series on all pipe materials, even on such challenging ones as fiber-reinforced plastic (FRP) pipes. The outstanding performance of FLEXIM is shown by thousands of references worldwide.

Advantages

• Very low installation costs and zero pipe interference

• Extremely accurate down to flow velocities as low as 0.01 m/s

• No zero calibration needed and permanently drift-free

• Permanent coupling pads

• IP68 transducers

• Transducers can be permanently buried (no chamber required)

• Drift-free measurements

• Reliable and accurate data

• Low installation costs

• Built to last

• Works on difficult pipes

Applications

• Water & Sewage

- Potable Water Treatment

- Water network monitoring and leak detection

- Wastewater Treatment

Technical Facts

Measurement uncertainty

(volumetric flow rate) ±1 % of reading ±0.005 m/s Repeatability0.15 % of reading ±0.005 m/s Flow velocity range0.01...25 m/s Ex zone transmitteronly safe area Power supply100-230VAC, 24DC, 12DC Available transducerShear Wave for Ex zones--- for pipe sizes range50mm ... 6500mm for temperature range-40°C ... +130°C Outputs4-20mA active/passive

4-20mA HART active/passive

pulse/frequency/binaryInputs--- Digital communicationModbus RTU/TCP

BACnet MSTP/IP

M-Bus

Profibus PA

Foundation Fieldbus Additional InformationFor more detailed Information please download the Technical Specifications

관리자 2020.06.08

5

Ultrasonic Flow Meter (FLUXUS F501)

The Ideal Solution for the Water Industry

Designed for the needs of the Water Utilities sector

The FLUXUS F501 is FLEXIM's solution for many flow metering applications found in the potable water distribution sector and adjacent industries.

The FLUXUS F501 offers a precise bi-directional flow measurement over a wide turndown ratio - not only at high, but especially at low flow velocities. Due to its matched and paired transducers, it also guarantees a superior zero stability.

Whereas the standard FLUXUS F501 comes with water-tight IP67 transducers, the product variant FLUXUS F501IP is equipped with a set of IP68 transducers.

The F501IP is thus the ideal solution for subsurface installations. With the transducers residing inside the stainless steel VARIOFIX C fixture, the measurement system is optimally protected and a long lifetime ensured.

As of its high repeatability, the FLUXUS F501 also offers the possibility for leak detection. Especially at night, when temperatures are more even and only low flow velocities are common in drinking water lines, leakages can clearly be identified and such reading transferred to a process control system.

The ideal retrofit solution for water pipes

As a non-invasive clamp on flow meter, the FLUXUS F501 is the ideal solution for retrofitting in existing networks. As there is no need for interruption of supply lines and costly shaft constructions, it is thus also the much more cost effective solution in comparison to conventional metering technologies such as magnetive inductive meters.

Due to the non-invasive technology, no cutting or welding work is needed to mount the transducers on the pipe. During installation, the flow meter's user interface is automatically adapted to the connected transducers and no zeroing is necessary. Water is already pre-selected as medium and it's physical properties are stored in the flowmeter's memory.

In most cases only the pipe's outer diameter and wall thickness as well as the water temperature has to be entered in order to start the measurement. The commissioning work is thus reduced to a minimum. On request, the instrument can even be pre-configured at the factory.

Advantages

• Precise bi-directional, highly dynamic flow measurement

• Water-tight transducers (IP67) for outside use

• Virtually maintenance free - permanent coupling pads instead of frequent regreasing

• Simple retrofitting in existing networks and systems - no need for pipe work

• User-friendly menu navigation - the firmware is specifically adapted to the needs of the water industry

• For nominal pipe diameters of 10mm up to 2500mm - highly cost effective

• Superior pipeline leak detection - high repeatability of accurate measurement readings

• Digital Signal Processing ensuring stable and reliable results even under difficult measurement conditions

• High measuring accuracy, even at low flow velocities due to matched transducers

Applications

• Industrial and Municipal Energy Management

- Buildings Cold and Heat Metering

- District Heat Metering

- Industrial Energy Efficiency

• Water & Sewage

- Potable Water Treatment

Technical Facts

Measurement uncertainty

(volumetric flow rate)±1.5 % v. MW ±0.01 m/s Repeatability0.25 % v. MW ±0.01 m/s Flow velocity range0.01...25 m/s Ex zone transmitteronly safe area Power supply230VAC, 12/24VDC Available transducerShear Wave for Ex zones--- for pipe sizes range10mm ... 2400mm for temperature range-40°C .... 100°C Outputs1x 4-20mA active

2x pulse/binary Inputs--- Digital communicationModbus RTU

BACnet MS/TP

M-Bus

관리자 2020.06.08

Designed for the needs of the Water Utilities sector

The FLUXUS F501 is FLEXIM's solution for many flow metering applications found in the potable water distribution sector and adjacent industries.

The FLUXUS F501 offers a precise bi-directional flow measurement over a wide turndown ratio - not only at high, but especially at low flow velocities. Due to its matched and paired transducers, it also guarantees a superior zero stability.

Whereas the standard FLUXUS F501 comes with water-tight IP67 transducers, the product variant FLUXUS F501IP is equipped with a set of IP68 transducers.

The F501IP is thus the ideal solution for subsurface installations. With the transducers residing inside the stainless steel VARIOFIX C fixture, the measurement system is optimally protected and a long lifetime ensured.

As of its high repeatability, the FLUXUS F501 also offers the possibility for leak detection. Especially at night, when temperatures are more even and only low flow velocities are common in drinking water lines, leakages can clearly be identified and such reading transferred to a process control system.

The ideal retrofit solution for water pipes

As a non-invasive clamp on flow meter, the FLUXUS F501 is the ideal solution for retrofitting in existing networks. As there is no need for interruption of supply lines and costly shaft constructions, it is thus also the much more cost effective solution in comparison to conventional metering technologies such as magnetive inductive meters.

Due to the non-invasive technology, no cutting or welding work is needed to mount the transducers on the pipe. During installation, the flow meter's user interface is automatically adapted to the connected transducers and no zeroing is necessary. Water is already pre-selected as medium and it's physical properties are stored in the flowmeter's memory.

In most cases only the pipe's outer diameter and wall thickness as well as the water temperature has to be entered in order to start the measurement. The commissioning work is thus reduced to a minimum. On request, the instrument can even be pre-configured at the factory.

Advantages

• Precise bi-directional, highly dynamic flow measurement

• Water-tight transducers (IP67) for outside use

• Virtually maintenance free - permanent coupling pads instead of frequent regreasing

• Simple retrofitting in existing networks and systems - no need for pipe work

• User-friendly menu navigation - the firmware is specifically adapted to the needs of the water industry

• For nominal pipe diameters of 10mm up to 2500mm - highly cost effective

• Superior pipeline leak detection - high repeatability of accurate measurement readings

• Digital Signal Processing ensuring stable and reliable results even under difficult measurement conditions

• High measuring accuracy, even at low flow velocities due to matched transducers

Applications

• Industrial and Municipal Energy Management

- Buildings Cold and Heat Metering

- District Heat Metering

- Industrial Energy Efficiency

• Water & Sewage

- Potable Water Treatment

Technical Facts

Measurement uncertainty

(volumetric flow rate)±1.5 % v. MW ±0.01 m/s Repeatability0.25 % v. MW ±0.01 m/s Flow velocity range0.01...25 m/s Ex zone transmitteronly safe area Power supply230VAC, 12/24VDC Available transducerShear Wave for Ex zones--- for pipe sizes range10mm ... 2400mm for temperature range-40°C .... 100°C Outputs1x 4-20mA active

2x pulse/binary Inputs--- Digital communicationModbus RTU

BACnet MS/TP

M-Bus

관리자 2020.06.08

내용이 없습니다.