Ultrasonic Flowmeter

- 조회수

- 1256

Safe media detection during tank filling and transfer processes

Non-invasive Media Detection for reliable protection against hazardous mix-ups

The false media fill-up of chemicals during delivery and transfer from tank trucks into storage tanks can have fatal consequences.

These mix-ups lead to serious accidents again and again, especially when acids and alkalis are mixed. In order to prevent such dangerous situations, the hazardous substances committee recommends monitoring of the filling line.

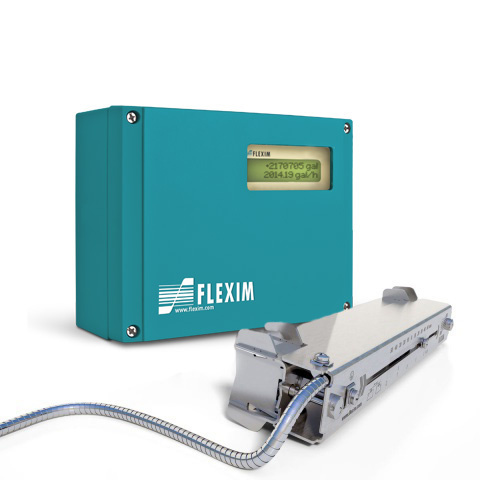

FLEXIM developed the PIOX ID clamp-on ultrasonic media identification system for this purpose.

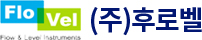

Sonic velocity – a characteristic media property

PIOX ID determines the acoustic velocity of the medium using clamp-on ultrasonic transducers mounted on the outside of the filling lines. The acoustic velocity is a substance-specific variable and constant at a given temperature. Given the acoustic velocity’s dependence on the media temperature, this is also measured by PIOX ID.

If the acoustic velocities of two media differ, these can be identified by way of measurement. In particular, since the acoustic velocities of acids and alkalis are very different from one another, the safety function can be implemented easily and reliably due to the significant measuring effect.

A significant application of PIOX ID is the reliable detection of sodium hypochlorite. If sodium hypochlorite is in contact with an acid, a violent exothermic reaction occurs in which toxic chlorine is released. Many other chemicals carry similar risks. Chemical mix-ups can have disastrous consequences, be it explosions or the formation of dangerous substances such as nitrous gases or hydrogen chloride.

These dangers must be controlled safely. PIOX ID offers protection. The media identification system ensures that acids and caustics can never be confused.

State-of-the-art redefined

PIOX ID is a proven innovation in practice. The non-invasive media identification system was developed in collaboration with experts on safety at work. Unlike other methods such as temperature and pH measurement, the acoustic measurement technology is completely wear-free and does not require any maintenance. National rules for the handling of hazardous substances thus recommend the use of ultrasonic measurement as an appropriate technique for monitoring the filling line.

PIOX ID is factory preconfigured so that the protection function can be set up easily and reliably. The media identification system releases the filling process only if the value for the acoustic velocity measured by PIOX ID is within the range of the target value for the target medium. In all other cases, the filling process is stopped.

The selection of the target medium is made either according to the customer‘s specification at the factory or by an authorised person when the device is put into operation. In normal operation mode after commissioning, it is no longer possible to make changes to the stored parameters. The transmitter then only indicates whether the desired target medium is in the pipe, the pipe is empty, or a wrong medium is present and there is therefore a risk.

Advantages

• Reliable, non-invasive media detection with clamp-on ultrasonic transducers mounted on the outside of the pipe

• Effective increase in plant, operational and working safety

• Unrestricted process-focussed measurement method, significant measuring effect

• Practically maintenance-free measurement, no wear due to mechanical stress or chemical corrosion

• Tamper-proof

• Recognised state-of-the-art measurement technology

Applications

• Industry Solutions

- Food & Beverage

Technical Facts

| Measurement uncertainty (volumetric flow rate) | n.a. |

| Repeatability | n.a. |

| Flow velocity range | n.a. |

| Ex zone transmitter | only safe area |

| Power supply | 230VAC, 24VDC |

| Available transducer | Shearwave |

| for Ex zones | --- |

| for pipe sizes range | DN25 ...DN65 |

| for temperature range | -40°C .... 100°C |

| Outputs | 1x 4-20mA active (status) 2x binary (status) |

| Inputs | 1x Pt100/Pt1000 |

| Digital communication | --- |

게시물수정

게시물 수정을 위해 비밀번호를 입력해주세요.

댓글삭제게시물삭제

게시물 삭제를 위해 비밀번호를 입력해주세요.